Milled Parts

At Radical Fabrications, our CNC and manual milling services deliver precision, repeatability, and versatility for a wide range of industries and applications. From complex multi-axis geometries to tight-tolerance components, we routinely achieve tolerances as close as ±0.001".

Every part we produce is made from premium, American-sourced materials and is machined start-to-finish in our own shop here in the United States. This hands-on approach ensures unmatched quality, exceptional durability, and reinforces our commitment to keeping manufacturing right here at home.

We approach each project with a problem-solving mindset, optimizing designs for strength, manufacturability, and cost efficiency while never compromising on accuracy or finish. Whether it’s a single prototype or a high-volume production run, we take pride in delivering parts that meet the highest standards, every time.

4th Axis Milled Component – Automotive Application

Machined from aluminum on a vertical CNC mill with a 4th axis rotary table. This part required a precise cylindrical milling path to produce complex spline features along its circumference. By programming the rotary and linear motions in sync, all machining was completed in a single setup, ensuring perfect alignment and a uniform surface finish.

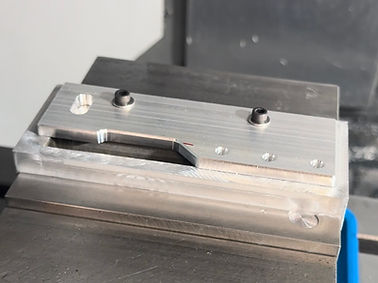

Precision Verification Component

Produced from aluminum on a vertical CNC mill to verify machine accuracy and process control. This part featured multiple critical dimensions held to a tolerance of ±0.001". Achieving this level of precision required careful toolpath programming, stable workholding, and optimized feeds and speeds to minimize thermal expansion and cutter deflection.

Heavy-Duty Billet Radiator Brackets

Reverse-engineered and manufactured from billet aluminum to replace original stamped components on a heavy-duty haul truck. The original brackets, including damaged samples, were used as reference to redesign for improved strength, durability, and fit. Machined on a vertical CNC mill, the billet construction provides superior rigidity and longevity compared to the original stamped aluminum parts, ensuring reliable support for the truck’s oversized radiator.

Racing Brake Drum Modification

Modified a high-performance racing drum, machined from 7075 aluminum, to accommodate a custom brake rotor installation. The job required precision boring of existing stud holes on a vertical manual mill to achieve an exact fit while maintaining proper alignment. This service demonstrates the ability to perform quick, accurate modifications without the setup time of CNC programming, ideal for time sensitive needs.